when you need to depend on aluminium die casting

you can depend on shivam

Pressure Die Casting

The high-pressure die casting process is the fastest and most cost-effective manufacturing process available for producing precise, high-integrity, net-shape aluminium components.

We have a long experience in producing high quality aluminium die castings requiring close tolerances, pressure tightness, good surface finish, and various secondary operations.

Our technical expertise, thoughtfully designed processes and leading edge technology enables us to offer you high quality & cost effective solutions.

Sectors We Serve

We have capabilities to meet high pressure aluminium die casting, CNC/ VMC machining and finishing needs of a wide variety of industries -

- Automotive Industries

- Electrical Industries

- Appliances Industries

- LED Lighting Industries

End-to-end Casting Solutions

R&D / Product Development Support

High Quality

Production

We develop all required Tools and Molds in-house.

Our leading edge production technology and our online/offline QC processes always assures you highest quality products.

Post Processes & Assemblies

We also provide component assembly services.

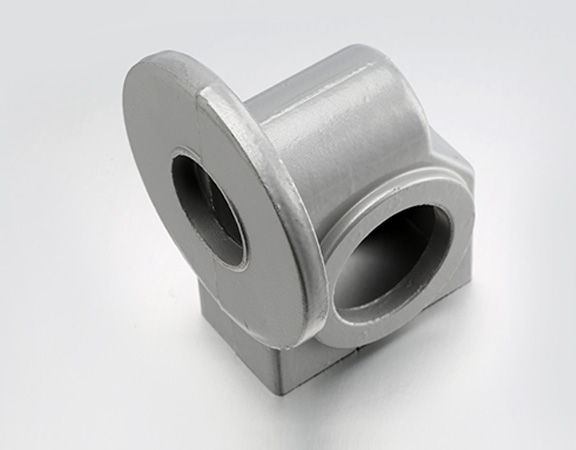

Few of Our products

In-house Facilities

that ensures quality and aids our production capabilities.

Design Department

Our team coordinates with your product development team to bring out die casted products of your desired specifications.

It is involved in tool & die making and further coordinates with our production department to set the processes to acheive minimum machine time, quick setup and precise tolerances, which in turn eliminate secondary operations.

Mold Making Facilities

Our in-house mold making facility delivers Quality aluminium components by ensuring -

- Dimensional Precision

- Controlled Porosity Level

- Material Flow Analysis

- Required Surface Finish

Well Equiped Toolroom

We have state-of-the-art toolroom for making any type of tool for core box and intricate dies.

Our team of experts matches to the latest technology machinary and in tandem they bring up tools that brings accuracy while increasing productivity.

Component Testing Lab

Our in-house lab is well equipped to perform various tests including chemical analysis, physical testing, mechanical testing, porosity analysis and metrology of die casted components